Main Form Products > Fabrics > Fabrics - PTFE Coated Fiberglass

Fiberglass Woven Fabrics with PTFE Coatings

Fiberglass Woven Fabrics with PTFE Coatings

PTFE Soft Coated Fiberglass Gasket Sealing Fabrics - High Temperature Chemical Resistant

550°F / 287°C Continuous Exposure: Higher Intermittent

FlameShield™ high temperature, heat resistant and chemical resistant fabric offers the advantage of a non-asbestos material with a higher temperature range and with excellent resistance to almost all solvents, caustics and acids. This fabric makes an excellent gasket material and is a milk white color.

The base fiberglass fabric is rated to 1000°F / 537°C, while the PTFE (Teflon) coating melting point is 620°F / 327°C.

Available in 5 weights / thicknesses, in roll widths of 40" and 60", and in roll lengths of 50 yards - or 25 yards for heavier items.

- 24 oz/yd .060" thick 40" and 60" roll width

- 30 oz/yd .065" thick 40" and 60" roll width

- 36 oz/yd .075" thick 40" and 60" roll width

- 40 oz/yd .090" thick 40" and 60" roll width

- 64 oz/yd .125" thick 40" and 60" roll width

The PTFE is applied to the fabric by dipping the fabric through an immersion tank of liquid PTFE dispersion. The fabric is then air dried as it leaves the dip tank. The result is a PTFE coating on the fabric which is soft, robust and flexible; however, it can be abrasively removed from the fabric with aggressive fingernail scraping, resulting in a thinner and thinner layer of PTFE remaining with each pass.

The coating follows the contours of the fabric, and the weave of the fabric remains prominent, however, the PTFE causes the yarns to be sealed and the small gaps between the yarns filled, resulting in an almost totally air-tight / liquid-tight fabric.

PTFE Resin Coated Fiberglass Non-Stick Fabrics with self silicone or acrylic adhesive backing

High Temperature Heat Resistant - Non-Stick surface. Used for bagging and sealing equipment heat strip applications - Non-stick guides

Premium Grade and Industrial Grade

550°F / 287°C Continuous Exposure: Higher Intermittent

FlameShield™ This high temperature, heat resistant and chemical resistant fabric with self adhesive backing and a release film is used in packaging as a non-stick release surface on heat sealers, blister and form fill sealing equipment. Used on guide rails chutes and slides. Excellent resistance to almost all solvents, caustics and acids. High dielectric strength.

Used as an insulation buffer for RF sealing, and as a surface cover on L Bar, Impulse and Bag sealers. This material is a tan color.

The base fiberglass fabric is rated to 1000°F / 537°C, while the PTFE coating melting point is 620°F / 327°C.

Available in roll widths of 38" in a roll length of 36 yards. (Adhesive thickness is extra).

- .003" thick 38" roll width

- .005" thick 38" roll width

- .006" thick 38" roll width

- .010" thick 38" roll width

The PTFE resin is applied to the fabric in a hot process and under pressure, causing a total impregnation of the base fabric. The surface of the resin is smooth and it takes considerable and aggressive force to scratch the ptfe surface to remove it from the fabric with fingernail scraping.

Available in Standard and Premium grades. Premium grade has an almost perfectly smooth surface while standard grade surface has some profiling of the underlying base fabric. Available with Silicone or Acrylic adhesive.

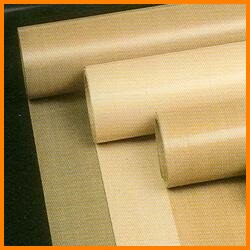

Fiberglass Fabric with PTFE Resin Impregnation FDA Compliant - 21CFR177.1550 for direct food contact

Non stick non-adhesive fabric for food processing

550°F / 287°C Continuous Exposure: Higher Intermittent

FlameShield™ This high temperature, heat resistant and chemical resistant fabric is used for pan liners and conveyors in baking applications and is FDA compliant for food contact - meets 21 CFR 177.155. Used on guide rails chutes and slides. Excellent resistance to almost all solvents, caustics and acids.

This material is a tan color.

The base fiberglass fabric is rated to 1000°F / 537°C, while the PTFE coating melting point is 620°F / 327°C.

Available in 5 weights / thicknesses, in roll widths of 36 to 39.5" in a roll length of 18 and 36 yards. This fabric may be slit to any width to use as a narrow fabric or tape.

The PTFE resin is applied to the fabric in a hot process and under pressure, causing a total impregnation of the base fabric. The surface of the resin is smooth and it takes considerable and aggressive force to scratch the ptfe surface to remove it from the fabric with fingernail scraping.

Available in Standard and Premium grades.

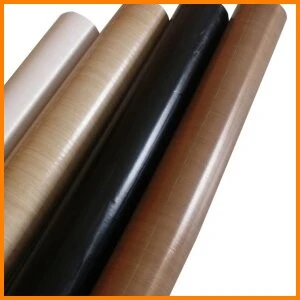

Fiberglass Fabric with PTFE Resin Impregnation - Anti-static and conductive

Non stick non-adhesive anti-static and conductive fabric

550°F / 287°C Continuous Exposure: Higher Intermittent

FlameShield™ high temperature, heat resistant and chemical resistant fabric is anti-static / conductive. Suitable for sensitive electronics covers and conveyor systems that normally have static buildup. Excellent resistance to almost all solvents, caustics and acids.

This material is a black color.

The base fiberglass fabric is rated to 1000°F / 537°C, while the PTFE coating melting point is 620°F / 327°C.

Available in 2 weights / thicknesses, in roll widths of 36 to 39.5" in a roll length of 18 and 36 yards. This fabric may be slit to any width to use as a narrow fabric or tape.

The PTFE resin is applied to the fabric in a hot process and under pressure, causing a total impregnation of the base fabric. The surface of the resin is smooth and it takes considerable and aggressive force to scratch the ptfe surface to remove it from the fabric with fingernail scraping.