Main Form Products > Fabrics > Fabrics - Heat Reflecting

Radiant Heat Reflective Coating Fabrics

FlameShield™ Radiant heat reflective fabrics are available in the following groups:

- Aluminum foil coated fiberglass

- Aluminized PET film coated fiberglass

- Aluminized PET film coated aramid

- Stainless Steel foil coated fiberglass

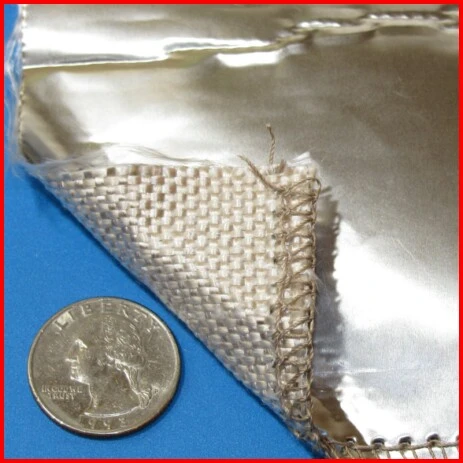

These fabrics provide protection from radiant heat with a heat reflective coating or lamination. One side is coated with either an aluminum foil or aluminized PET film, or stainless steel foil. Reflects more than 95% of the radiant heat that contacts its surface. Excellent radiant heat protection from sources such as super-hot metal slabs, proximity to liquid metal, infrared heaters, open flame / plasma or engine exhaust manifolds.

Can be cut into shapes and fastened into place with standard fasteners such as rivits, screws and bolts and also sewn with industrial sewing machines.

300°F / 149°C Continuous Exposure: Higher Intermittent

FlameShield™ high temperature, heat resistant fabric is partially heat treated to remove organics, set the weave dimensionally and reduce fray and loose fibers.

500°F / 260°C Continuous Exposure: Higher Intermittent

Dual-Coat™ high temperature fabric is a high temperature, heat resistant dual coated (aluminum film one side - silicone rubber one side) fabric that reflects radiant heat and is the perfect protection material for equipment covers such as cylinders bellows, that require a vapor barrier on the side opposite the heat reflecting side.

Also available with black color silicone coated side.

400°F / 204°C Continuous Exposure: Higher Intermittent

AluMaxTM high temperature, heat resistant poly-layered aluminized PET coated fabric reflects radiant heat and is the perfect protection for covering equipment that is in close proximity to intense radiant sources such as super-hot metal slabs, liquid and molten metals or glass, open flame/plasma or engine exhaust manifolds. Excellent long term flexibility for use in garments, with or without liner materials.

400°F / 204°C Continuous Exposure: Higher Intermittent

AluMaxTM high temperature, heat resistant poly-layered aluminized PET coated Aramid fabric reflects radiant heat and is the perfect protection for covering equipment that is in close proximity to intense radiant sources such as super-hot metal slabs, liquid and molten metals or glass, open flame/plasma or engine exhaust manifolds. Excellent long term flexibility for use in garments, with or without liner materials.

1000°F / 537°C Continuous Exposure: Higher Intermittent

FlameShield™ high temperature, heat resistant stainless steel foil coated fabric (stainless steel foil coated) reflects radiant heat and is the perfect protection for covering equipment that is in close proximity to intense radiant sources such as super-hot metal slabs, liquid and molten metals or glass, open flame/plasma or engine exhaust manifolds.