Main Form Products > Insulations / Felts

Insulation Materials for Blanket systems and shields

Tadpole gasket tapes are used in a variety of sealing and gasketing applications. They offer easy mounting - the tail can be held in place with grab bars or strips, mechanical fasteners with backing washers, or in some applications adhesively.

Silicone Closed Cell Insulating Sponge Foam - High temperature and heat resistant - low thermal conductivity

428°F / 220°C Continuous Exposure: Higher Intermittent

DeltaMaxä silicone sponge foam low thermal conductivity insulation available in general purpose and UL94 V-0 rating.

Excellent insulation for thermal blankets in wet environments.

Clean cutting for clean-room applications.

Silicone Closed Cell Insulating Sponge Foam with Kevlar Fabric Facing - High temperature and heat resistant - low thermal conductivity

392°F / 200°C Continuous Exposure: Higher Intermittent

DeltaMaxä silicone sponge foam with Kevlar fabric facing on both sides - low thermal conductivity insulation.

Good abrasion and tear resistance. Good handling for fabrication purposes and sewable into shapes.

Meets:

· AITM2.0002B (Vertical 12 sec flammability test).

· AITM2.0010 Flame Penetration (aircraft cargo liner).

· AITM2.0007 Smoke Density.

· AITM3.0005 Toxic Gas Emission.

· Airbus ABS5026 B01 / DAN 1226-03 specifications

Silicone Closed Cell Insulating Sponge Foam with Aluminized Fabric Facing - High temperature and heat resistant - low thermal conductivity

392°F / 200°C Continuous Exposure: Higher Intermittent

DeltaMaxä silicone sponge foam with Aluminized fabric facing on one side - low thermal conductivity insulation.

Thermal management for engine compartments, Electronic enclosures, HVAC systems.

Thermal

conductivity of 0.067 W/m °K.

Areal density: 2.5mm thickness – 0.83 kg/m2 / 0.17

lb/ft2

5.0mm

thickness – 1.17 kg/m2 / 0.24 lb/ft2

The foam component of this lamination meets

EN45545 / 49CFR238 / NFPA 130 / BS6853 (legacy) for HL3 requirements in R2 / R3

/ R22 / R23 applications (passenger railcars).

The foam component also meets various standards

for Surface Flammability (ASTM E162 / ASTM D3675), Smoke Density (ASTM E662), Toxic

Gas Generation (SMP 800-C), Flame Spread (ASTM C1166) and Heat Release (ASTM

E1354).

The 2.5mm thickness lamination meets ASTM

E162, ASTM E662 and SMP 800C.

Needled Nomex Insulation Felt - High temperature and heat resistant

450°F / 230°C Continuous Exposure: Higher Intermittent

FlameShield™ high temperature and heat resistant needled Nomex® insulation felt pads are fabricated from high quality yarns that will not burn and will withstand continuous exposure to temperatures of 450°F / 230°C. It provides excellent protection for industrial wires, cables, hoses (hydraulics), tube and pipes and also provides thermal insulation and personnel protection.

Available in various thicknesses, and also available reinforced with resin to add stiffness.

Needled Kevlar Insulation Felt - High temperature and heat resistant

850°F / 450°C Continuous Exposure: Higher Intermittent

FlameShield™ high temperature and heat resistant needled Kevlar® insulation felt pads are fabricated from high quality yarns that will not burn and will withstand continuous exposure to temperatures of 850°F / 450°C. It provides excellent protection for industrial wires, cables, hoses (hydraulics), tube and pipes and also provides thermal insulation and personnel protection.

Available in various thicknesses, and also available reinforced with resin to add stiffness.

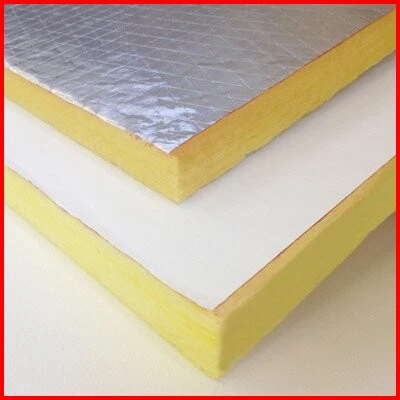

Rigid Mineral Wool Insulation Board - Marine Approved - High temperature heat resistant and thermal insulating

1200°F / 550°C Continuous Exposure: Higher Intermittent

FlameShield™ Rigid mineral wool board is marine approved and hydrophobic.

Suitable for A-30 Steel Bulkhead, A-30 Steel Deck, A-60 Steel Bulkhead, A-60 Steel Bulkhead (restricted) and A-60 Steel Deck.

Reinforced aluminum foil facing on one side. Also available plain (no facing) or with white fiberglass cloth one side.

Flame spread Index = 0, Smoke development index = 0.

(ASTM E84 (UL 723), CAN/ULC S102)

(ASTM E84 (UL 723), CAN/ULC S102)

Thermal resistance: R-value/inch 75°F: 4.1 hr.ft2/BTU (0.72m2K/W)

Thermal conductivity: .24 (BTU.in/hr.ft2.°F) at 75°F

Water absorption: <1% Weight

Suitable for steel pin or wire mesh support installation. Easily cut to size.

US Coast Guard Certificate of Approval: 164.107/16/0, 164.107/17/0, 164.109/26/0, 164.112/142/0

Transport Canada Certificate of Approval: LRTC 10-60002, LRTC 10-60001, LRTC 10-60004

Lloyds Register Certificate of Approval: SAS F090281, SAS F090280, SAS F090283

Fiberglass Needled Insulation Lagging Felt / Batt - High temperature heat resistant and thermal insulating

1200°F / 550°C Continuous Exposure: Higher Intermittent

FlameShield™ This high temperature, heat & flame resistant thermal insulating (lagging) needled fiberglass insulation is fabricated from high quality type E fiberglass that will not burn and will withstand continuous exposure to temperatures of 1100°F / 593°C. This product can provide thermal insulation for equipment, valves, piping, exhaust systems and is often used as the filler material for insulating blankets and covers. Also provides personnel protection.

This material resists most acids and alkalis and is unaffected by most bleaches and solvents. It is highly flexible and conformable.

Available in 1/4", 1/2", 3/4" and 1" thickness.

- Conforms to MIL-I-16411 Type II.

- Meets US Coast Guard 164.009 for incombustible materials.

- Meets MIL-I-24244 for corrosiveness.

- NSN: 5640-00-173-6591

Thermal conductivity (K) is .43 at 500°F and .536 at 649°F.

Fiberglass Needled Blanket

Needled Fiberglass Insulation Blanket. Roll widths are 60" (152cm).

$ 0.00

Add CofC or Test Reports for Products

CofC and Test Report documentation can be added to your order using the cart.

Add CofC or Test Reports for Products

CofC and Test Report documentation can be added to your order using the cart.

Silica Non-woven Insulation Felt / Batt - High temperature heat resistant and thermal insulating

2000°F / 1093°C Continuous Exposure: Higher Intermittent

InSilPro™ high temperature, heat & flame resistant thermal insulating (lagging) non-woven silica insulation is fabricated from high purity base fibers. Low thermal conductivity, easy to handle, cut, shape and fabricate.

Flat orientation thermal conductivity of 0.18 at 200°F; 0.20 at 400°F; 0.23 at 600°F; 0.26 at 800°F.

This material resists most acids and alkalis and is unaffected by most bleaches and solvents. It is highly flexible and conformable.

Available in 7/32 (5mm) and 13/32 (10mm) thickness at a density of 8 lbs/cubic foot.

Fiberglass Needled Blanket

Silica non-woven Insulation Blanket.

$ 0.00

Silica Needled Insulation Lagging Felt / Batt - High temperature heat resistant and thermal insulating

1900°F / 1037°C Continuous Exposure: Higher Intermittent

InSilMax™ InsulBatt™ 1800 High Temperature needled silica insulation (lagging) is fabricated from high quality Silica that will not burn and will withstand continuous exposure to temperatures of 1900°F / 1037°C with excursions to 2300°F / 1260°C.

This material resists most acids and alkalis and is unaffected by most bleaches and solvents. It is highly flexible and conformable. Available in 1/8", 1/4", 1/2" & 1" thickness.

Shot-free and manufactured from continuous filament silica yarns (6 micron diameter fiber). Applications for these products include thermal insulation and/or protection of equipment such as piping, valves, engine components, turbine casings, as well as affording personnel protection from high temperature plant equipment. Stress relief customers utilize this product as it provides high re-use cycles due to its strength.

For 1" material tested to ASTM C177 (test density 9.98 lbs/ft2):

- at 92°C/198°F Apparent Thermal Conductivity is 0.0448 (SI) or .310 (British) Thermal Resistance is 0.482 (SI) or 2.73 (British)

- at 203°C/397°F Apparent Thermal Conductivity is 0.0589 (SI) or .408 (British) Thermal Resistance is 0.366 (SI) or 2.08 (British)

- at 316°C/600°F Apparent Thermal Conductivity is 0.0764 (SI) or .530 (British) Thermal Resistance is 0.282 (SI) or 1.60 (British)

- at 537°C/999°F Apparent Thermal Conductivity is 0.1235 (SI) or .856 (British) Thermal Resistance is 0.175 (SI) or 0.99 (British)

- at 649°C/1200°F Apparent Thermal Conductivity is 0.1558 (SI) or 1.080 (British) Thermal Resistance is 0.138 (SI) or 0.79 (British)

Apparent Thermal Conductivity is W/m-K (SI) or Btu-in/hr-F-ft2 (British)

Thermal Resistance is m2-K/W (SI) or hr-F-ft2Btu (British)

Ceramic Fiber Needled Insulation Lagging Felt / Batt - High temperature heat resistant and thermal insulating

2000°F / 1093°C Continuous Exposure: Higher Intermittent

CerMax™ Extreme high temperature and heat resistant needled ceramic fiber insulation (lagging) is an excellent replacement to asbestos. Light-weight, flexible and good handling strength. Provides low thermal conductivity and good dielectric strength and features excellent corrosion resistance.

This material is produced from an extremely pure alumino-silicate ceramic fiber non-woven material and can be used at 2300F continuously with excursions to 3000F / 1650C.

Can be layered with other materials for enhanced insulation protection.

Available in 1/2", 1" and 2" thickness and in 24" and 48" roll widths.

Applications for these products include thermal insulation and/or protection of equipment such as piping, valves, engine components, turbine casings, as well as affording personnel protection from high temperature plant equipment.