Main Form Products > Sleeve Groups > > Sleeves - Firesleeve Group

"Firesleeve" Sub-category

Firesleeve High Temperature, Heat, Flame, Fire Resistant Protection

Silicone Rubber Coated Fiberglass Sleeve & Jacket for Wire, Cable, Hose and Tube Protection

500°F / 260°C Continuous Exposure

800°F / 426°C Short Term Exposure

2200°F / 1205°C Excursions

3000°F / 1650°C Peak Exposure

FlameShield™ Firesleeve (sometimes spelled fire sleeve or fire-sleeve) is the perfect sleeve and jacket choice for protecting industrial hydraulic hoses and lines, pneumatic lines, fuel & oil lines, brake lines, wires and cables from exposure to high temperature, heat, flame, fire and pyro exposure. The extra thick special formulation of silicone rubber on our firesleeve sheds molten metals, slag, welding splatter, electrical or grinding sparks and contamination.

Industrial Grade Firesleeve - Knit & Heavy Duty Braid

FlameShield™ industrial grade Firesleeve is fabricated from a knitted fiberglass yarn substrate, while the heavy duty industrial grade Firesleeve is fabricated from a thicker and denser braided fiberglass yarn.

Available in sizes ranging from 0.25" Inside Diameter through 5" I.D. in 27 size steps.

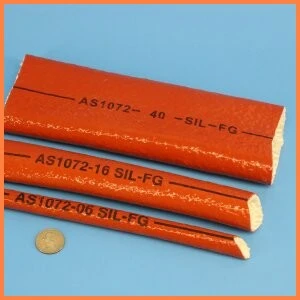

Firesleeve - Aviation Aerospace Grade meeting SAE AS1072E

Allows qualified hose assemblies to pass AS1055D testing

FlameShield™ aviation / aerospace grade high temperature, heat, flame and pyro resistant firesleeve jacket is manufactured to SAE AS1072E standards so it can pass the fire testing standards of AS1055D; and the requirements of FAA TSO - C53a and TSO - C75. Meets 14 CFR 25.869(a)(4); Appendix F, Part 1(b)(7) (60-degree flammability Test).

It may be used for all fuel, oil, hydraulic, fire extinguisher and prop feathering lines. "Fire-proof" hose lines, as defined by the FAA, must withstand a direct flame for fifteen minutes under specified flow conditions without failure. Fire-resistant lines must withstand a 5 minute exposure under these conditions.

Fire-proof hose lines are obtained when the proper size Firesleeve is selected and properly assembled with appropriate clamps.

Standard colors are oxide-red and black - other popular colors are silver-grey, blue, yellow and green. Available in sizes ranging from 0.25" Inside Diameter through 5" I.D. in 25 size steps.

Firesleeve - SAE AS1072E Aerospace/Aviation Grade NSN NATO part numbers

Cage Code L8347

DualShield™ Dual Layer Heavy Duty Firesleeve -

High Temperature, Heat, Flame & Fire Resistant Silicone Rubber Coated Fiberglass Sleeve & Jacket for Wire, Cable, Hose and Tubing Protection

DualShield™ Firesleeve (sometimes spelled fire sleeve or fire-sleeve) is the perfect sleeve and jacket choice for protecting industrial hydraulic hoses and lines, pneumatic lines, fuel & oil hose lines, brake lines, wires and cables from exposure to high temperature, heat, flame, fire and pyro exposure. The extra thick special formulation of silicone rubber on our firesleeve sheds molten metals, slag, welding splatter, electrical or grinding sparks and contamination. Firesleeve also provides protection from ozone, UV and abrasion. Meets 14 CFR 25.869(a)(4); Appendix F, Part 1(b)(7) (60-degree flammability Test).

The first sleeve is overbraided with another layer of full coverage fiberglass that is also silcione rubber coated, This dual layer firesleeve offers the highest level of protection of any firesleeve against flame exposure, fire, molten metal and glass, slag and sparks.

The dual layer sleeve is available with any standard color as the inner sleeve and any standard color as the outer cover..The most popular colors are oxide-red and black.

Normally supplied in 50 & 100 foot lengths, but custom by-the-foot lengths are also available.

Available in sizes ranging from 0.25" Inside Diameter through 5" I.D. in 27 size steps.

Firesleeve with VELCRO® Brand Hook & Loop Closure

Available in two styles: HiFlex and LoFlex. HiFlex is manufactured from braided Heavy Duty Firesleeve, and LoFlex is manufactured from woven base 98oz/sq-ft fabric. Meets 14 CFR 25.869(a)(4); Appendix F, Part 1(b)(7) (60-degree flammability Test).

The HiFlex silicone coating and underlying braid fiberglass is flexible, allowing for easy placement on curved lines and for installations requiring high flexibility and motion. The LoFlex is a stiffer material, providing slightly more protection than the HiFlex product due to the silicone having a high durometer.

Firesleeve with Metal Snap Closure

SnapSleeve™ firesleeve povides a field installable protection sleeve utilizing metal snaps instead of hook and loop closure strips. Meets 14 CFR 25.869(a)(4); Appendix F, Part 1(b)(7) (60-degree flammability Test).

Snaps are typically installed at 4 or 6 inch spacing along the sleeve. Additional snaps may easily be field installed to allow for unique bends or extra closure protection.

Available in sizes from 1" through 12" ID. Other larger sizes available.

Firesleeve with Zipper Closure

ZipSleeve™ firesleeve provides a field installable protection sleeve utilizing a nomex zipper with brass teeth instead of Velcro closure strips. Meets 14 CFR 25.869(a)(4); Appendix F, Part 1(b)(7) (60-degree flammability Test).

Available in standard sizes from 1" through 12" ID; custom sizes are available.

The standard maximum length of a zipper firesleeve is 50 feet / 15 metres. Longer zippers up to 150 feet / 45 metres are possible, but will incur minimum order quantities.

Small Diameter Firesleeve for AWG sized Wire Protection

High Temperature, Heat & Flame Resistant Protection for Wire, Cables, Hoses and Tubing

464°F / 240°C Continuous Exposure: Higher Intermittent

FlameShield™ thin-wall high temperature, heat, flame and fire resistant firesleeve is the perfect choice for protecting small diameter wires and cables from exposure to high temperature and environmental conditions. The thin-wall fiberglass substrate and smooth silicone rubber on this firesleeve sheds light molten metal splash, slag, welding splatter, electrical or grinding sparks, solder drips and contamination. Also provides protection from ozone, UV and light abrasion. This product is UL/CSA approved and used on a wide variety of equipment such as fixtures, appliances and motors for wiring protection.

This sleeve is available only in oxide-red and black. Supplied in spool lengths; some sizes may be available in by-the-foot lengths - please contact our order desk to enquire.

Small Diameter Firesleeve for AWG sized Wire Protection - Heavy Duty Wall Thickness

High Temperature, Heat & Flame Resistant Protection for Wire, Cables, Hoses and Tubing

464°F / 240°C Continuous Exposure: Higher Intermittent

FlameShield™ Heavy-duty wall high temperature, heat, flame and fire resistant firesleeve is the perfect choice for protecting small diameter wires and cables from exposure to high temperature and environmental conditions. The heavy-duty wall fiberglass substrate and thicker smooth silicone rubber on this firesleeve sheds light molten metal splash, slag, welding splatter, electrical or grinding sparks, solder drips and contamination. Also provides protection from ozone, UV and light abrasion. This product is UL/CSA approved and used on a wide variety of equipment such as fixtures, appliances and motors for wiring protection.

This sleeve is available only inoxide-red. Supplied in spool lengths; although some sizes may be available in by-the-foot lengths - please contact our order desk to enquire.

Firesleeve Accessories: End Cut Liquid Dip & Paste Sealant, Clamps & Tools, End Wrap Tape

Protecting and sealing the cut ends of firesleeve from wicking liquids and contaminants

SleeveSeal™

SleeveSeal™ high temperature sealant paste is our special formulation of high-temperature silicone rubber, packaged into a convenient 3oz squeeze tube or 10.3oz caulking tube, for use on mechanical joints, and as a potting compound, anywhere a high-temperature adhesive/sealant is required. 2 grades: +260°C and +300°C continuous.

Seal-Dip™ is a special formulation of our high-temperature silicone rubber which is a liquid until exposed to air, when it cures rapidly into a flexible protective covering of silicone rubber. Perfect for protecting the ends of sleeve and tape from fraying, or from contamination, and from wicking liquids such as water, oil, hydraulic fluid, etc. Usually used as a dip for sleeve and rope. Non corrosive and meets Mil-A-46146 as per NAVAIR 01-1A-20.

SleeveSeal End Wrap Tape

This high temperature, heat and flame resistant silicone rubber end wrap tape is the perfect choice for sealing the ends of firesleeve, thereby preventing the firesleeve from wicking liquids such as water, oil or hydraulic fluid. This silicone tape can also be used to help secure other types of fiberglass and silica tapes over wires, cables, hoses, tube and pipe..

The tape has a blue stripe running down the centre as an aid to performing a standard 50% overlap when wrapping the tape around Sleeve, hoses and cables.

End-wrap silicone rubber tape is self bonding to itself and other silicone rubber sleeve and tape, providing a waterproof/air tight end to the installation of firesleeve sleeve over hoses and cables. This tape is available in 1" and 1 1/2" widths (25 & 37mm), with 36 feet of tape per roll. The tape is mounted on a backing film for easy unwinding. Also available meeting specification A-A-59163 / Mil-I-46852 and Mil-I-22444.

End-wrap silicone rubber tape is self bonding to itself and other silicone rubber sleeve and tape, providing a waterproof/air tight end to the installation of firesleeve sleeve over hoses and cables. This tape is available in 1" and 1 1/2" widths (25 & 37mm), with 36 feet of tape per roll. The tape is mounted on a backing film for easy unwinding. Also available meeting specification A-A-59163 / Mil-I-46852 and Mil-I-22444.

|

|

|