Applications - All > Applications - General

OSHA (Occupational Safety and Health Administration) Personnel Burn Protection Solutions

OSHA (Occupational Safety and Health Administration) Personnel Burn Protection Solutions.

OSHA does not have a specific standard or guideline set regarding specific temperatures objects must be limited to so as to protect workers from accidental contact burns.

OSHA does consider exposed heated surfaces to be a hazard if there is a potential for injury. There are two specific citations that can be used for guidance: 1910.261(k)(11) and 1910.262(c)(9).

1910.261(k)(11) Steam and hot-water pipes. All exposed steam and hot-water pipes within 7 feet of the floor or working platform or within 15 inches measured horizontally from stairways, ramps, or fixed ladders shall be covered with an insulating material, or guarded in such manner as to prevent contact.

1910.262(c)(9) Steam pipes. All pipes carrying steam or hot water for process or servicing machinery, when exposed to contact and located within seven feet of the floor or working platform shall be covered with a heat-insulating material, or otherwise properly guarded.

Taking these two paragraphs into account with the requirement that all exposed heated surfaces are a hazard if there is a potential for injury (burn), then not only water and steam pipes are a concern, but any pipe, hose, or other surface that is hot by any cause (hot gas, electrically heated, etc.) needs to be protected from accidental contact from personnel.

But how much insulation is required and what temperature drop is required?

Through experience, it has generally been accepted by workplace health and safety professionals that metallic items that are above 140°F / 60°C should be protected in a manner so that accidental contact will not produce a burn. Therefore, a target temperature of 140°F / 60°C and below is desirable for metallic objects. Therefore one can also think that any insulation system on a hot pipe or hose should therefore also have a maximum surface temperature of 140°F / 60°C.

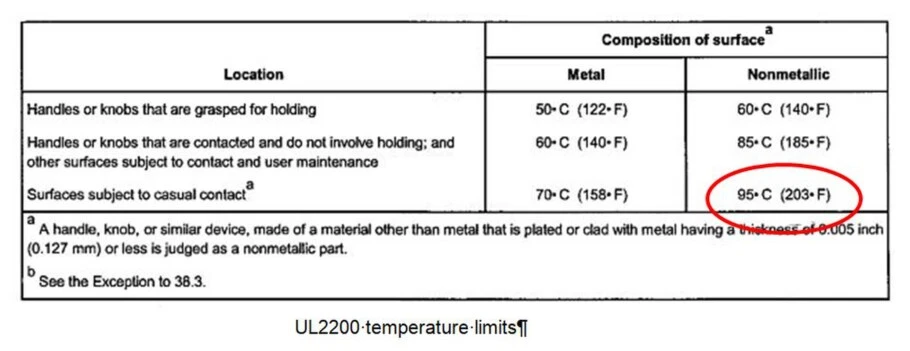

There is a standard, UL2200, which does provide some specific temperature numbers for use with engine driven generators, and of interest they differentiate metallic from non-metallic items. It is important to remember that metals conduct heat, and most thermal protection systems (insulation, fabrics, tapes, etc.), do not. This means that the insulation system surface can be “hotter” than a metal surface and still be “touch safe”.

Products that may be used to provide accidental contact burn protection from hot metal pipes:

Products to help meet OSHA requirements

Engine blankets to cover engine exhaust components. (Engineered to provide a temperature drop at the surface of the blanket within OSHA/UL2200 limits)

Insulated Wrap for hot piping and hoses. (Engineered to provide a temperature drop at the surface of the wrap)

Sleeves to install over pipes, hoses, tubing, etc. (how thick a layer of sleeve and what kind of sleeve material?)

For industrial applications where the hot object surface temperature is 1000F and below, typically a 1/2" to 1" layer of fiberglass braided or knitted sleeve insulation will provide a temperature drop to close to the safe touch temperature. To reduce the temperature even further usually requires a significantly thicker layer - as the most thermal insulation value gain is typically in the first inch, and adding another inch may only provide an additional 5 to 15% drop. Since most sleeves are typically 1/16" (1.5mm) to 1/8" (3mm) thick, you can see it will take multiple layers to achieve the total thickness required.

If the surface temperature is higher than 1200F, then other materials than fiberglass should be considered. The thickness layer may then be more in the realm of 1.5 to 3 inches for example at temperatures of 1500F to 1800F.

For surface temperatures up to 1200F: Link to Sleeves for Thermal Protection

For surface temperatures up to 1800F: Link to Sleeves for Thermal Protection

For surface temperatures up to 2300F: Link to Sleeves for Thermal Protection

Tapes to install over pipes, hoses, tubing, etc. (How much and what kind of tape should be used?)

Woven or knitted tapes can be wound in an overlapping fashion down the length of a pipe, hose, tube, etc., and then held into position with a clamp, a yarn of the tape, or a section of the tape cut-off in a short length. Tapes may be easier to keep overwinding than installing multiple sleeves. Most popular tapes are available in 1/32, 1/16, 1/8 and 1/4" thick.